Post by merlin on Dec 29, 2009 10:42:15 GMT -5

Hi All,

I posted this awhile back at CLIMB's website. I figured to share it here to those interested.

Ceramic bearings has been around for many years. I first encounter them in Remote Controlled gas car hobby. Over the years, I learned that ceramic bearings rolled smoother than steel. This makes them more efficient when installed in key places in bike where friction can be reduced. There are some concerns about the reliability of ceramic bearing vs steel. In my opinion ceramic bearings are better than steel when placed in key locations to reduce friction and enhance performance.

Your rear hubs is one of the key locations that can benefit from ceramic bearings. A typical high performance rear hub uses 4 or more bearings. Industry Nine XC hubs uses 4 bearings in the back and 2 bearings in the front. They are rated at ABEC5 and are truly smooth. Ceramic bearings are rated higher and because you are replacing all 4 proves to reduce the most friction enhancing performance. The bike coasts faster further and smoother.

Finally, ceramic bearing upgrade is not for everyone. It is for someone who wants the ultimate in performance from their high performance hubs. There is no guarantee that it will win races. However it is guarantee to reduce friction when installed in key locations.

Thanks for reading!

The following is DIY Industry Nine XC hub maintenance and Enduro bearing upgrade.

Tools and supplies used:

Park cassette removal tool

5mm hex keys

1.5mm hex key

1.2mm hex key

18mm socket + extension

ball pin hammer

plastic hammer

scribe or c-clip remover

small pliers

Finishline synthetic grease

rags and degreaser etc.

For more detailed instructions, maintenance guide from Industry Nine is available in their website.

Remove cassette using appropriate tools. Counter clockwise to loosen.

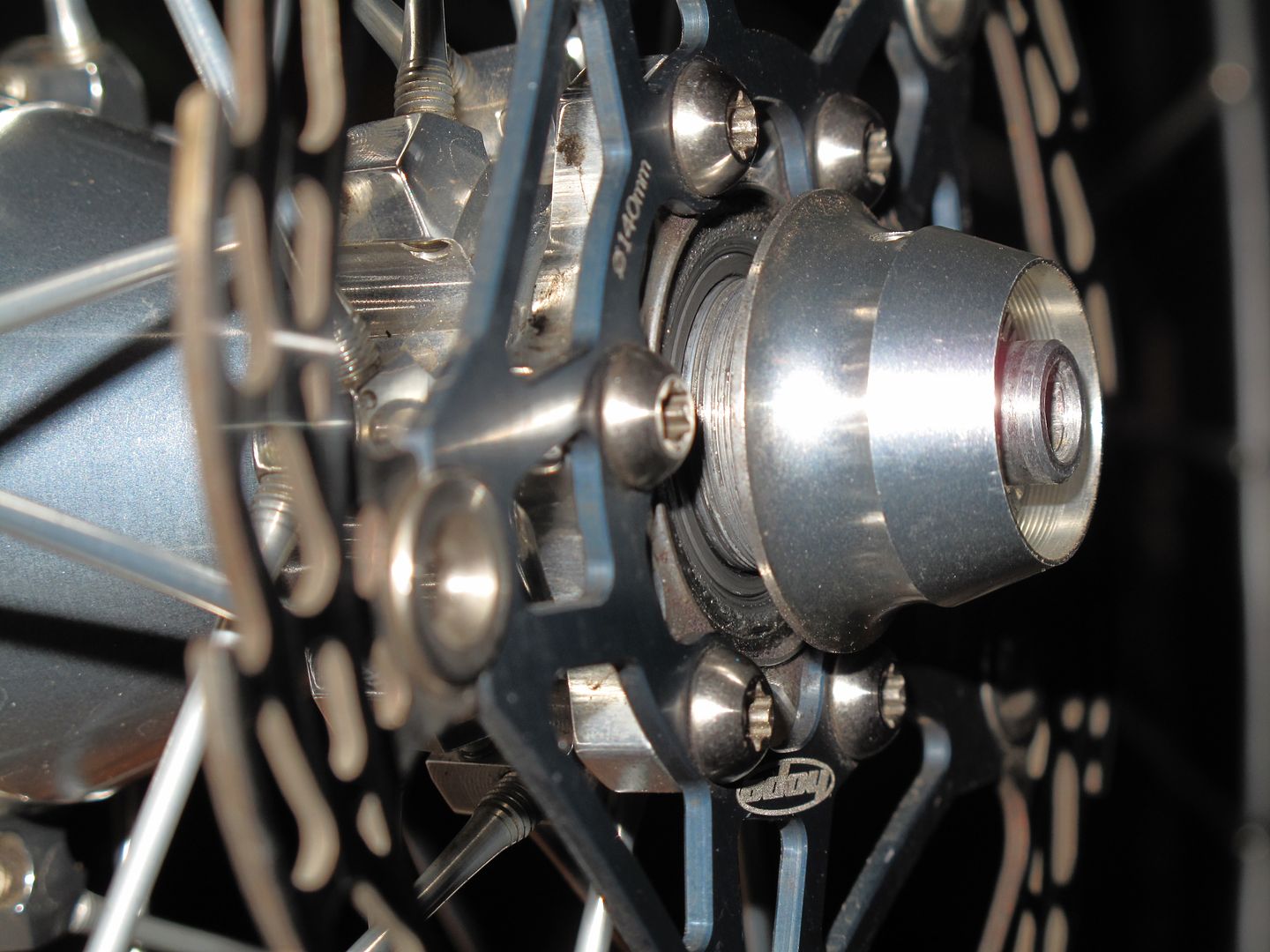

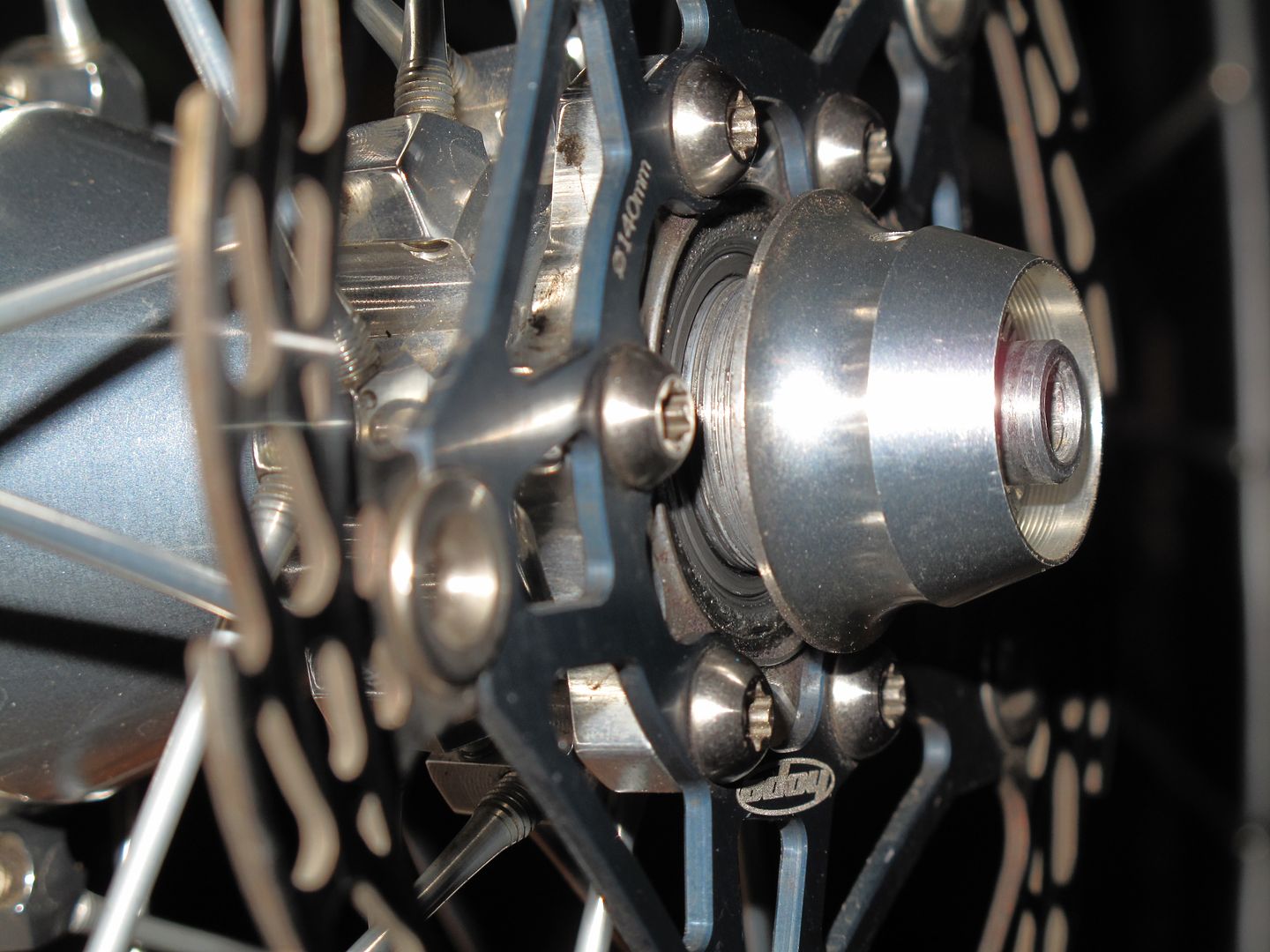

View with the cassette removed

Unscrew and remove the bearing tension and dustcap from the non-drive side

Pop out the drive and axle mechanism from the non-drive side using a soft plastic mallet.

I posted this awhile back at CLIMB's website. I figured to share it here to those interested.

Ceramic bearings has been around for many years. I first encounter them in Remote Controlled gas car hobby. Over the years, I learned that ceramic bearings rolled smoother than steel. This makes them more efficient when installed in key places in bike where friction can be reduced. There are some concerns about the reliability of ceramic bearing vs steel. In my opinion ceramic bearings are better than steel when placed in key locations to reduce friction and enhance performance.

Your rear hubs is one of the key locations that can benefit from ceramic bearings. A typical high performance rear hub uses 4 or more bearings. Industry Nine XC hubs uses 4 bearings in the back and 2 bearings in the front. They are rated at ABEC5 and are truly smooth. Ceramic bearings are rated higher and because you are replacing all 4 proves to reduce the most friction enhancing performance. The bike coasts faster further and smoother.

Finally, ceramic bearing upgrade is not for everyone. It is for someone who wants the ultimate in performance from their high performance hubs. There is no guarantee that it will win races. However it is guarantee to reduce friction when installed in key locations.

Thanks for reading!

The following is DIY Industry Nine XC hub maintenance and Enduro bearing upgrade.

Tools and supplies used:

Park cassette removal tool

5mm hex keys

1.5mm hex key

1.2mm hex key

18mm socket + extension

ball pin hammer

plastic hammer

scribe or c-clip remover

small pliers

Finishline synthetic grease

rags and degreaser etc.

For more detailed instructions, maintenance guide from Industry Nine is available in their website.

Remove cassette using appropriate tools. Counter clockwise to loosen.

View with the cassette removed

Unscrew and remove the bearing tension and dustcap from the non-drive side

Pop out the drive and axle mechanism from the non-drive side using a soft plastic mallet.